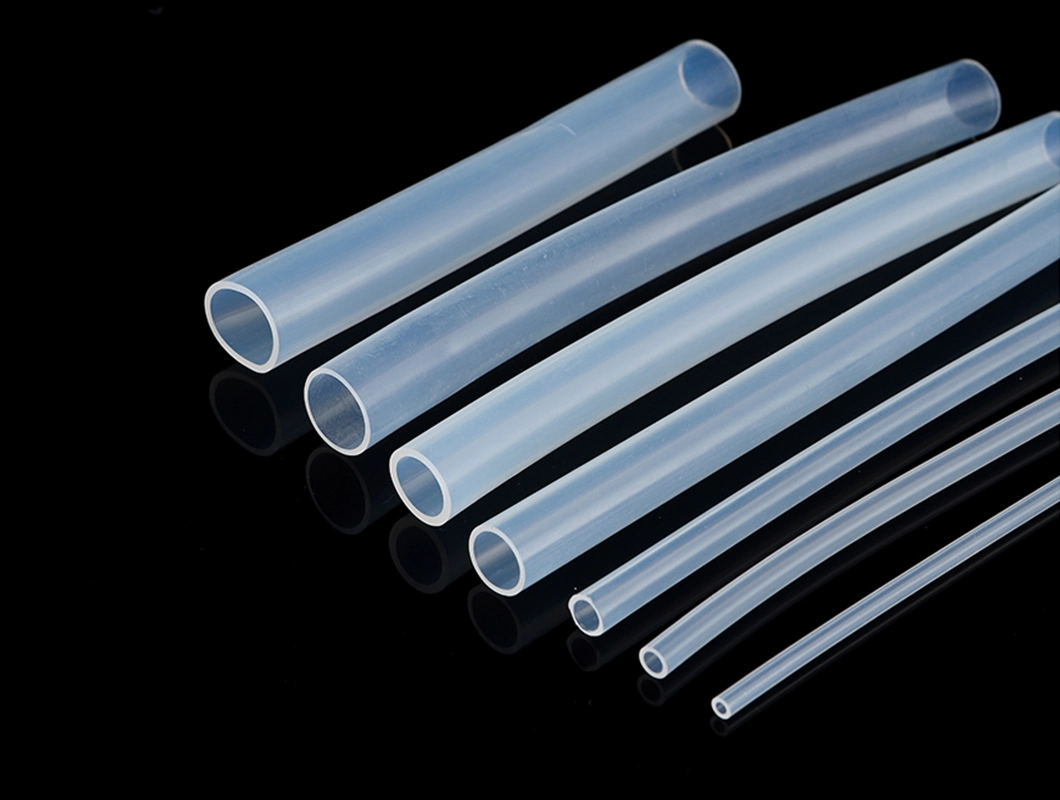

Custom White Transparent Translucent Plastic FEP Winding Pipe PTFE /FEP/Fpa Extruded Tube

Overview Package size per unit product 55.00cm * 55.00cm * 50.00cm Gross weight per unit product 13.500kg Product Descri

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | custom |

| After-sales Service | Online Technical Support |

| Warranty | 3 Years |

| Material | PFA |

| Kind | Thermosetting Plastics Pipe |

| Water Absorption | 1.5%~3.5% |

| Contraction Percentage | 2.0%~5.0% |

| Tensile Strength | 41~50MPa |

| MOQ | 100m |

| Color | Transparent, White and Other Colors |

| Working Temperature | - 80c to +260c |

| Free Sample | Available |

| Transport Package | Bag and Carton and Customized |

| Specification | Custom |

| Trademark | Siweier |

| Origin | China |

| HS Code | 39209910 |

| Production Capacity | 10000m/Day |

Packaging & Delivery

Package size per unit product 55.00cm * 55.00cm * 50.00cm Gross weight per unit product 13.500kgProduct Description

Product Description

| Name | FPA/PFA/FEP Tube |

| Large Size Rank | OD: 3mm~ 70mm; ID: 1.0mm ~60mm |

| Origin | China |

| Printing words | Customized |

| Material | FPA |

| Tensile Strength | 40~50MPa |

| Working Temperature | - 80°C to +260°C |

| Elongation | Elongation |

| Certificates | ISO 9001, TS16949, FDA, ROHS, SGS |

| Size | Standard or Customized |

| Color | Transparent, Blue,Red,Black,Green,Yellow or customization |

| Surface | Smooth |

| Free Sample | Available |

| Package | Pack in Roll with OPP Bag or Customized Package |

| Delivery Time | Shipped out within 1-7 days after receiving PO and payment(for new customer). |

| Freight | Sea (FCL & LCL) or air freight |

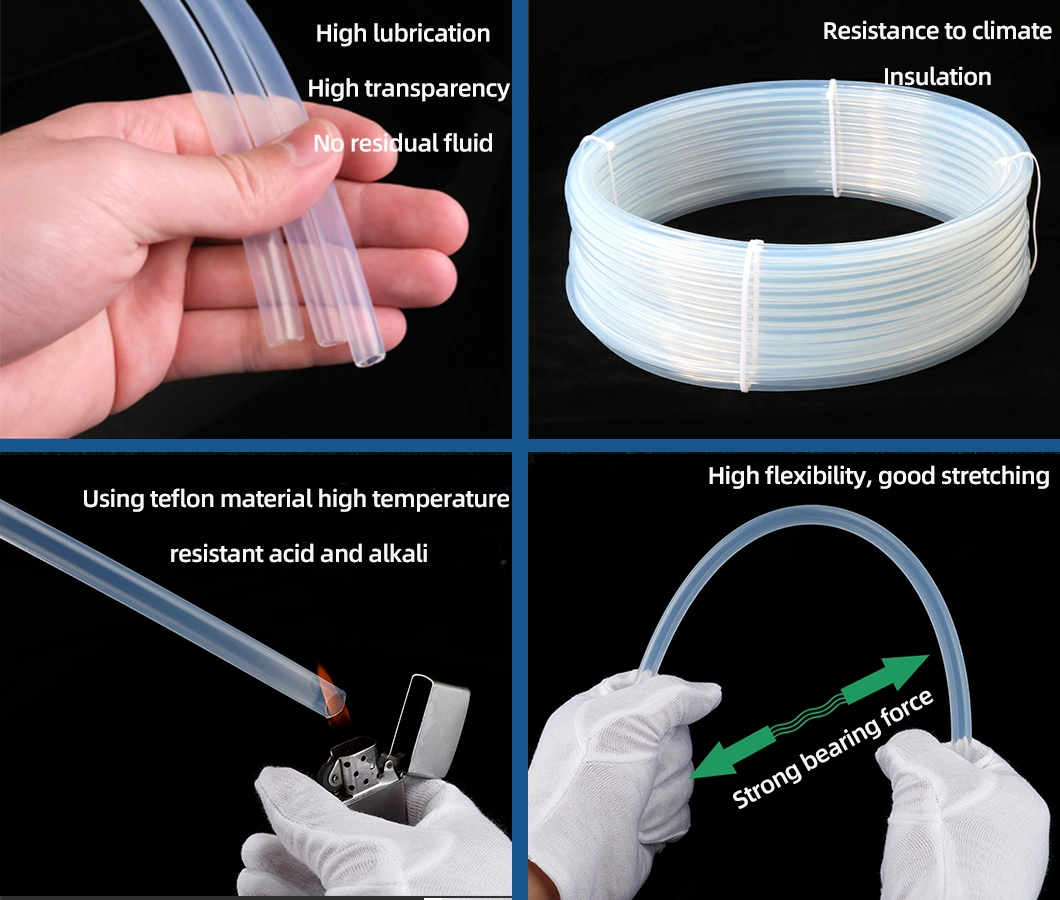

| Feature | 1.Operating temperature range: -70°C~260°C. 2.No-begriming ,no-stagnant in tube 3.Corrosion resistance, strong acid resistance, strong alkali resistance ,no poison with physical inertia ,high transparency. 4.Weather resistance ,can be hold under ozone and shine for long time ,easy to process for second time , self-close , self jointing, and self-turning. |

| Application | Widely used in semi-conductor product equipment , Heat exchange equipment ,machinery, electronic chemical industry, Pharmaceutical and other fields. |

Detailed Photos

Photo Show

Certifications

Company Profile

Suzhou Siweier Plastics Technology Co. Ltd. Is located in Suzhou, close to Shanghai, with a superior location and convenient transportation. The company was established in August 2009, covering an actual area of 14, 169 square meters. The company has formed a characteristic image of "complete specifications, many varieties, large quantities, fast delivery and high quality".

The main products include medical consumables, Silicone tubes, FEP / PFA Tube, Silicone Braided Hose, Pump Hose, PVC Hose, Silicone Products, Silicone Shaped Parts and so on.Through the efforts of all staff, the company has obtained ISO9001, ISO13485 management system certificate, IATF16949 automotive quality system certification, EU CE certificate, US FDA certificate and many other authoritative certifications.

The company has strong technical force, strong innovation and research ability, and can customize different specifications of products according to customer needs. We insist on the principle of "customer first, honesty and trustworthiness" to provide our customers with high quality products and attentive service.

Payment & Delivery

FAQ

Q1: Do you have your own factory?

A:Yes, we have our own factory established more than 12 years.

Q2: Silicone seems to be more expensive than other rubber, why is this?

A: Silicone is more expensive than most rubber types because it is a speciality high performance polymer with outstanding qualities. It is made in relatively low quantities and requires expensive and complicated primary manufacturing facilities.

Q3: What is the difference between 'curing' and 'vulcanization'?

A: The terms curing and vulcanization essentially describe the same thing - the transformation of the polymer into a cross-linked rubber.

Q4: Why is silicone used in food applications?

A: Silicone rubber is among a number of rubber types that can be used in contact with food. It has the advantage of being a low taint non-toxic material.

Q5: Do you provide sample? Is it for free or not?

A: Yes, if we have it in stock we can offer the sample for free , you need to pay for the freight cost to your country. The sample will be sent immediately by the air express in 3- 5 dayswhile .

Q6: When can you launch delivery after I placed order?

A: If there is stock, 2-5 days; if not, 15-30 days depends on the quantity.

Q7: Do you Accept OEM service?

A: YES, We can provide OEM&ODM service.

Q8:What's the Payment Terms?

A: Usually,30% as deposit,70% before shipment by T/TWestern Union acceptable for small amount. L/C acceptable for large amount. Scrow ,Paybal,Alipay are also ok

Q9:How you pack products?

A:Normally,plastic bag inside and carton outside .We'll do according to customers' requirement.

Q10: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou City, Jiangsu Province, China.It's takes 1.5 hours from Shanghai airport. We can pick you up if you need, welcome to visit our factory.

Q11: I am a small wholesaler,do you accept small order?

A: We can accept small order or trial order as long as it meets our MOQ and we would like to grow up with you together.

Related Products

-

![LED Tri-Proof Panel Light 4FT 40W Fixture Motion Sensor and Emergency Backup Supply Corrosion Resistance IP65 Waterproof Ik08]()

LED Tri-Proof Panel Light 4FT 40W Fixture Motion Sensor and Emergency Backup Supply Corrosion Resistance IP65 Waterproof Ik08

-

![High Quality Customizable Plastic Extruded Profiles, Custom Colors, Extruded PMMA Profiles]()

High Quality Customizable Plastic Extruded Profiles, Custom Colors, Extruded PMMA Profiles

-

![High Quality Car Dome Customization, Plastic Car Light Cover Customization]()

High Quality Car Dome Customization, Plastic Car Light Cover Customization

-

![Signage Signs Logo LED Channel Letters Flexible Lighting Lamp LED Strip Lights for Home Party Decor or Advertisement]()

Signage Signs Logo LED Channel Letters Flexible Lighting Lamp LED Strip Lights for Home Party Decor or Advertisement