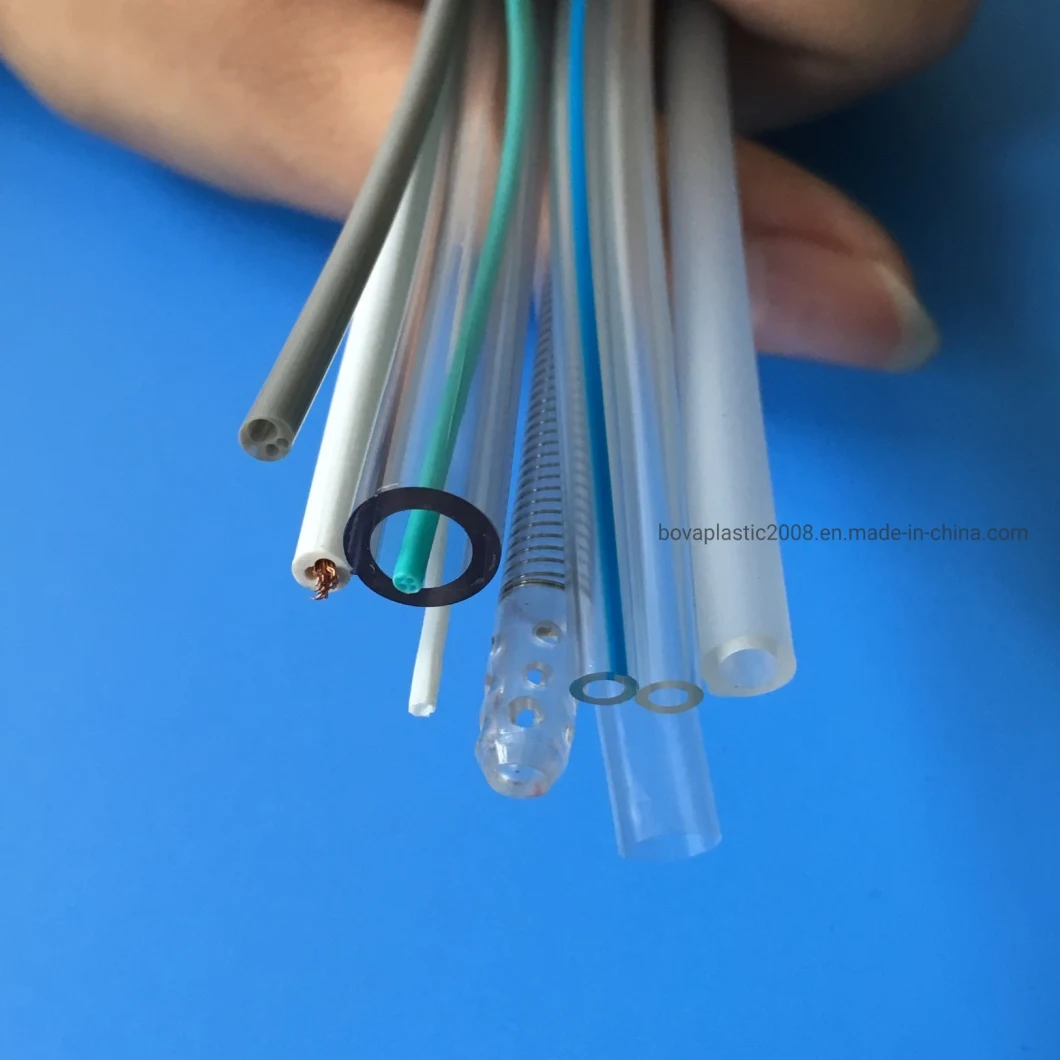

Extruded Flexible Plastic PU Medical Grade Tube with Develop

Overview Extruded Flexible Plastic PU Medical Grade Tube with Develop BOVA PROVIDES CUSTOM-MADE COMPONENTS FOR MEDICAL D

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | BV-PU1705 |

| Logo Printing | With Logo Printing |

| Color | Blue/White/Assignable |

| Transport Package | PE Bag/Master Carton/ Pellet |

| Specification | design by customer |

| Trademark | Bova |

| Origin | Suzhou China |

| HS Code | 9018909000 |

| Production Capacity | 50000/Week |

Product Description

Extruded Flexible Plastic PU Medical Grade Tube with DevelopBOVA PROVIDES CUSTOM-MADE COMPONENTS FOR MEDICAL DEBVICESProduct Description

Major Products:

Medical Grade PA/PEBAX tube, HDPE tube, LDPE tube, PU/TPU/TPE tube, PVC tube, PP/PE tube, PC tube, PS tube, ABS tube, etc.TPU Tube of TPU(Polyurethane) Series:

| Product name | TPU Tube |

| Material | Polyurethane |

| Size | OD: 0.8mm-11.0mm; ID: 0.2mm-10.0mm. |

| Tolerance | ±0.05mm-±0.15mm |

| Color | Nature/Customized |

| Develop condition | Transparent; 20-40% BaSO4. |

| MOQ | 500 meters |

| Package | PE bags into carton |

| Payment term | 100% T/T advance payment; or L/C at sight. |

| Delivery time | 15~25 days after order confirmed. |

Properties of PU (Polyurethane Tube)

1. High transparency.

2. Excellent hydrolysis resistance, oil resistance, mucedine resistance, and wear resistance.

3. Excellent biocompability, no cytotoxicity and skin irritation, sensitization to human body.

4. Excellent processing performance, TPU can be processed by using the usual methods of thermoplastic materials, such as injection molding, extrusion, rolling, etc. At the same time, TPU works together with certain polymer materials to produce polymer alloys that complement each other.

5. Low temperature resistance, can maintain good flexibility, softness and other physical properties at -35ºC.

6. Good tensile strength and elongation: TPU's tensile strength is 2-3 times of natural rubber or synthetic rubble.

Disposable wound edge protector:

Features of protector and retractor of surgical incision below:

1. made of high-quality nontoxic medical-grade PU.

2. it provide 360°protection for surgical cuts and 360°pulling without hurting.

3. reducing the infection of surgical cuts.

4. minimize the surgical cuts and maximize the explosion.

5. it provides best vision for surgical operation.

Material Characteristic

| HDPE | LDPE | PA12 | PEBAX | TPU | PP | |

| Density | 0.96 | 0.93 | 1.15 | 1.01 | 1.2-1.25 | 0.88 |

| Rigidity | 60D-65D | 48D-53D | 68D-70D | 23D-72D | 60A-75D | 60-69D |

| Max. Operation temperature | 54ºC | 54ºC | 80ºC | 80ºC | 80~100ºC | 80~100ºC |

| Min. Operation temperature | -40ºC | -40ºC | -40ºC | -20ºC | -35ºC | -20ºC |

| Tenacity | Commonly | good | commonly | commonly | Excellent | commonly |

| Color | Milk White | Translucent | Translucent | Transparent | Transparent | Translucent |

| Reprocessing performance Characteristics | Commonly | Easy | Easy | Easy | Easy | Commonly |

| Chemical Resistance | Good | Good | Good | Good | Commonly | Good |

| Insulation | Good | Good | Good | Good | Good | Good |

| Biocompatibility | Good | Good | Excellent | Excellent | Excellent | Good |

| Medical Grade Attestation | Yes | yes | yes | yes | yes | yes |

Company Profile

Our Company:

Kunshan Bova PlasticWas established in 2008, now located at NO.578 Jujin Road, Zhangpu Town, Kunshan City, Jiangsu Province.The company mainly provides precision extrusion catheter, secondary operation for catheter and catheter custom-made service.The company produces various materials such as TPU,PE,PP,PVC,Pebax,PA,PEEK,PSU,PPSU,PC,EVA,TPE,ABS,PCL,PLA,PTFE,FEP,Silica and various shapes of extruded pipes, such as single-lumen tubes, multi-row tubes, multi-color co-extrusion tubes, multi-layer coated tubes, X-ray development tubes, Thin-walled tube, metal-coated plastic tube, microcatheter, etc., The company has been committed to the production of plastic precision extrusion and catheter product research and development since its establishment.At present, the diameter deviation of extruded pipe can be controlled at ±0.02 mm, and the wall thickness can reach 0.06 mm.The company owns standard 100000 level clean room for production and passed ISO9001 quality system certification in 2016 and ISO13485 quality system certification in 2019.CertificationsPackaging & Shipping

Delivery:

For product in stock, we will ship within 3-5 days.For OEM product, please inquire.Transport Package:Double layer PE bags→Carton→PalletPayment Item:T/T ,50% Deposit, 50% Balance Before Shipment.FAQFAQ:

Example of the problem we can solve| Q Are you trading company or factory? |

| Q Can you manufacture the product without any burr? |

| Q Can you manufacture the colored tube in small quantities?There are no company accepting such product order. |

| Q Can you deal with the product whose thickness is so thin that it is difficult to manufacture? |

| Q Can you Manufacture the product in the company which is authorized by ISO 13485 and has the clean-room facility? |

| Q Can you provide free sample? |

Order Flow

ORDER FLOW:

CONTACTPlease let us know the specifications of the desired component via e-mail or Mobile phone.Verify prototype specificationsWe will confirm whether or not it is possible to produce according to specifications, and make suggestions if changes are necessary.Decide prototype specificationsWe will decide on the specifications after reaching an understanding(shape-quote,etc.)Receive ordersTake orders according to the specifications which are decided upon.Produce prototypesProduce prototypes using materials and manufacturing method according to specifications.Verify prototypeDouble check finished products within the company for products manufactured at cooperative companies.DistributionDelivery products with specifications as agreed upon in the quote.Need more information, pls feel free to contact us.

Related Products

-

![Customized Extruded PMMA & PC Lens for LED Light]()

Customized Extruded PMMA & PC Lens for LED Light

-

![OEM Custom CNC Industrial Lighting Heatsink Anodizing Heat Sink Profile Powder Coating Extruded Aluminum]()

OEM Custom CNC Industrial Lighting Heatsink Anodizing Heat Sink Profile Powder Coating Extruded Aluminum

-

![Low Price Wholesale Plastic Raw Material Injection Grade Pellets Modified ABS for Mechanical Parts]()

Low Price Wholesale Plastic Raw Material Injection Grade Pellets Modified ABS for Mechanical Parts

-

![High Voltage Waterproof LED Strip Light 110 220 Volts 2835 Flexible LED Rope Light]()

High Voltage Waterproof LED Strip Light 110 220 Volts 2835 Flexible LED Rope Light